Assessment framework

The Zero Carbon Fuel Monitor framework is structured into five main supply chain stages across the lifetime of a fuel, from natural resources to vessel propulsion.

The assessment process engages three criteria: Technology readiness (TRL), Investment readiness (IRL), and Community readiness levels (CRL).

A fuel is evaluated based on five ratings throughout the supply chain for TRL. For IRL and CRL, the onboard storage and handling stage is merged with the propulsion stage to form an overall ship stage, resulting in a fuel receiving four ratings.

Explore the framework in the dashboard, and find out more about the readiness levels, supply chain stages and fuel categories below.

Examine data on future fuels

Readiness levels explained

- Technology Readiness Level (TRL)

- Investment Readiness Level (IRL)

- Community Readiness Level (CRL)

The technology readiness level indicates the maturity of a solution within the research spectrum from the conceptual stage to being marine application-ready. It is based on the established model used by NASA and other agencies and institutes, using a 9-level scale.

- Basic principle observed

- Technology concept formulated

- First assessment feasibility concept and technologies

- Validation of integrated prototype in test environment

- Testing prototype in user environment

- Pre-production product

- Low scale pilot production demonstrated

- Manufacturing fully tested, validated and qualified

- Production and product fully operational

The investment readiness level indicates the commercial maturity of a marine solution on the spectrum from initial business ideas to reliable financial investments. It addresses all the parameters required for commercial success based on work by the Australian Renewable Energy Agency (ARENA) . The 6-level scale summarises the solution's commercial status and is determined by the available evidence in the market.

At each level, the assessment is made across several indicators that are key for successful commercialisation:

- Technical performance

- Financial proposition – costs

- Financial proposition – revenue

- Industry supply chain and skills

- Market opportunities

- Company maturity

- Hypothetical commercial proposition

- Commercial trial, small scale

- Commercial scale up

- Multiple commercial applications

- Market competition driving widespread development

- Bankable asset class

The community readiness level indicates the societal maturity of a marine solution in terms of acceptability and adoption by both people and organisations. It is gauged on the spectrum from societal challenge to widespread adoption. CRL is based on the work by ARENA2 and Innovation Fund Denmark3, adapted to a 6-level scale.

At each level, the assessment is made across several indicators that are key for successful adoption:

- Regulatory (safety)

- Regulatory (environment)

- Community acceptance

- Sustainability (lifecycle analysis or LCA)

- Sustainability (Environment)

- Sustainability (Social-economic)

- Stakeholder support or opposition is hypothetical

- Stakeholder support or opposition is becoming understood as a result of pilots

- Early-stage solution formation to tackle stakeholder issues

- Evidence becoming widespread, resulting in initial stakeholder acceptance

- Increased transparency and formalised processes driving momentum for change

- Processes well-defined to resolve stakeholder issues, with widespread stakeholder acceptance

Supply chain stages explained

- Resources

- Production

- Bunkering and ports

- Ship - onboard handling and storage

- Ship - propulsion

![]()

Resources refer to basic natural resources and feedstocks from which fuels are produced.

For example:

- Biomass feedstocks and transportation from field to bio-refinery

- Natural gas extraction and distribution

- Solar and windfarm (infrastructure, location, grid connection)

![]()

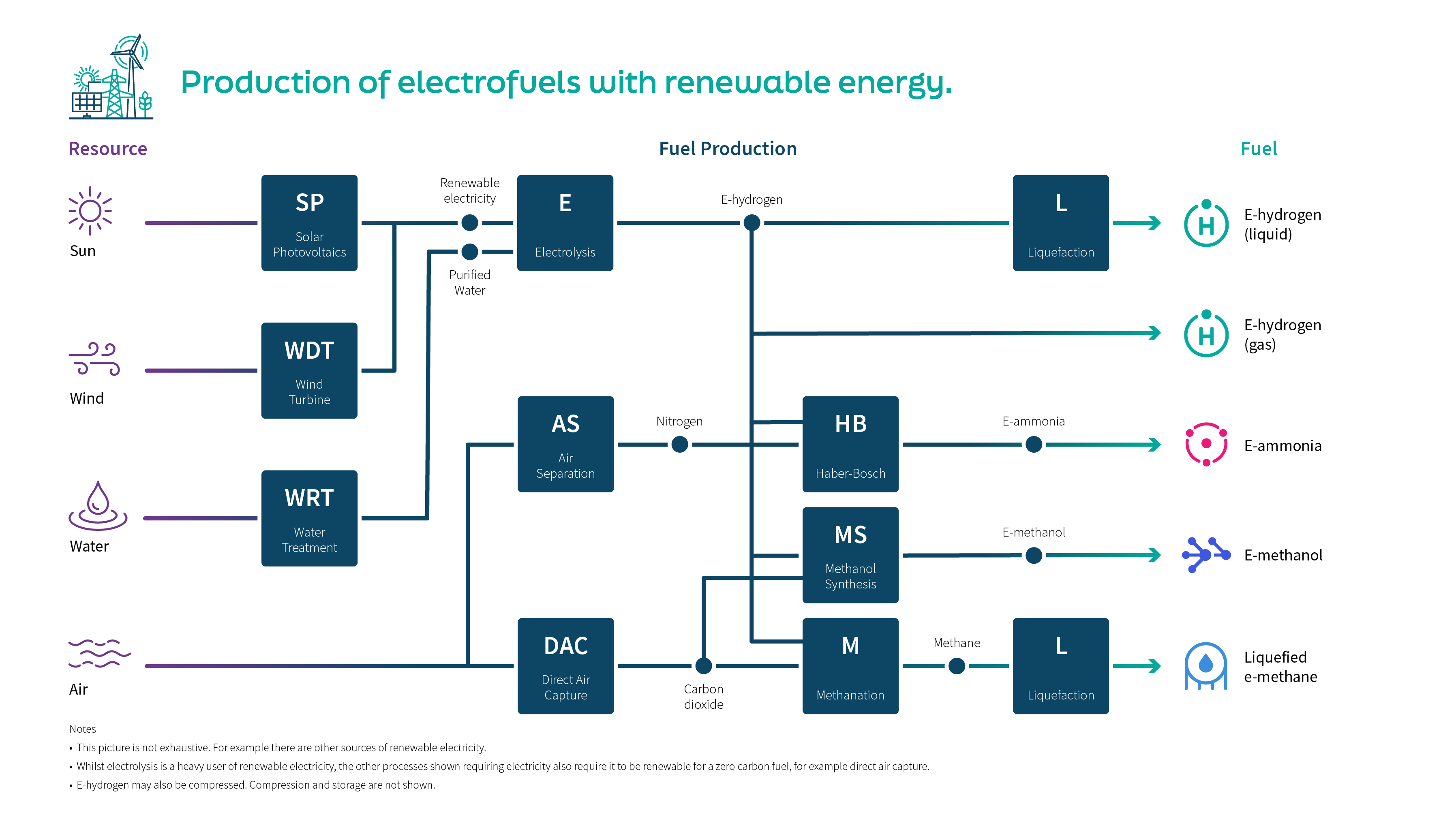

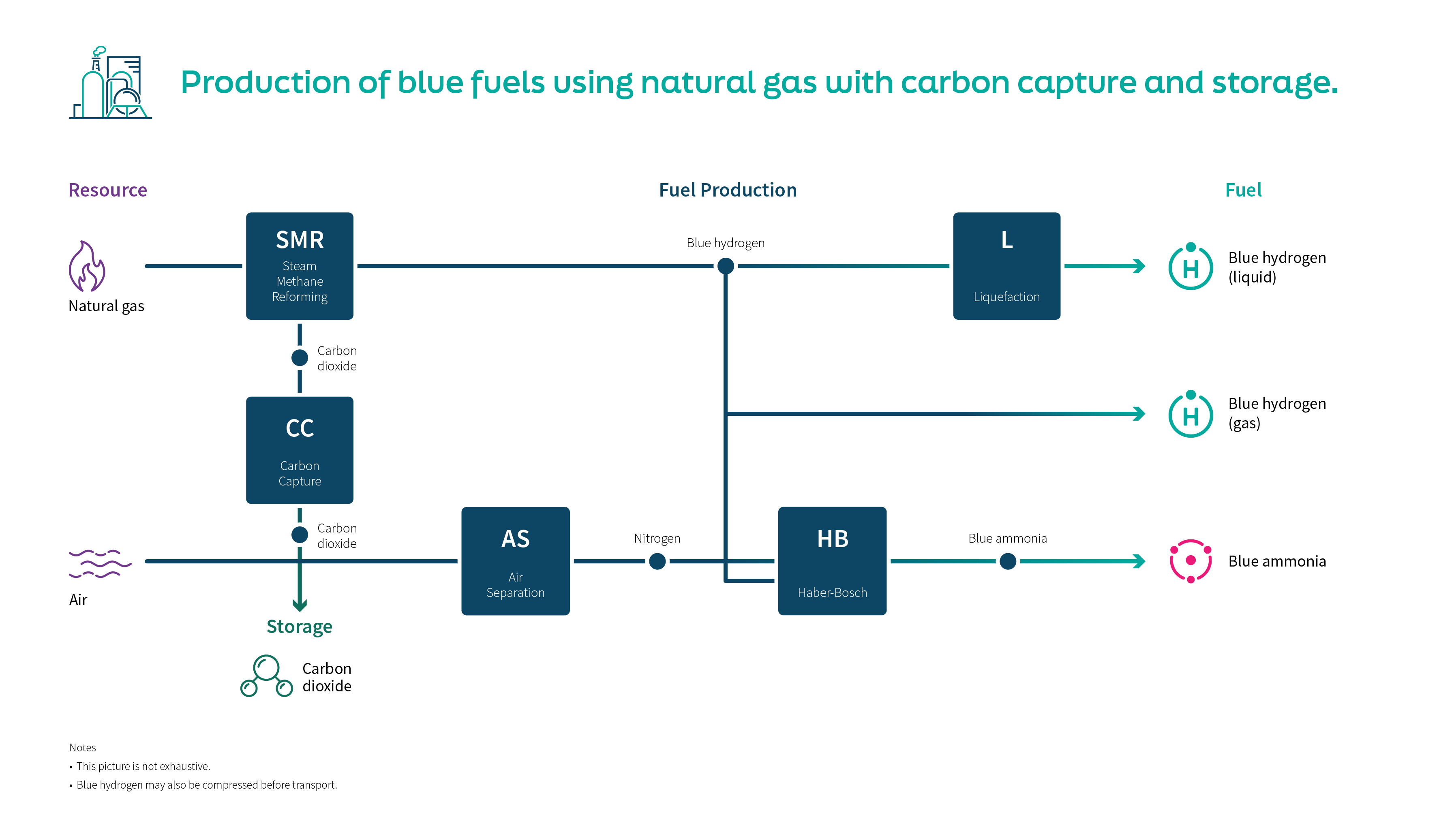

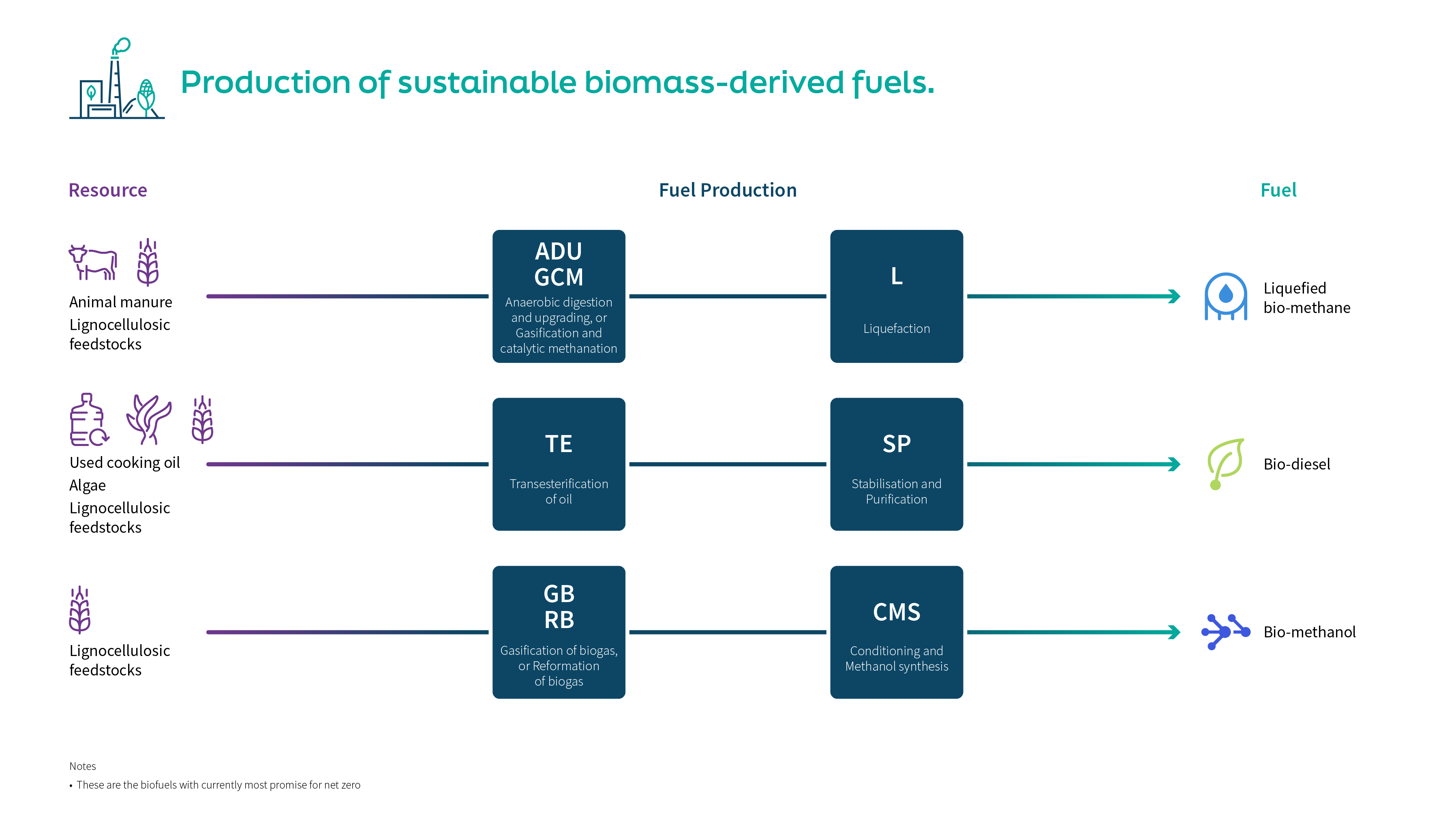

The production stage includes all processing of resources and intermediate products used to create fuels.

This includes:

- From resource to transportation at bunkering ports

- Fuel storage for buffering

- Transportation and distribution of intermediate and end products

- Chemical processes to produce molecules (e.g. electrolysis, Haber Bosch)

- Integration of production systems with wider energy system

![]()

This stage covers bunkering and ports integration, and includes:

- Refuelling stations

- Barges

- Berth

- Shore side storage

- Venting and detection

- Safety zone (including proximity to populated areas)

- Distribution of end product

![]()

The ship supply chain stage covers all operations onboard. IRL and CRL are assessed at this level.

![]()

Onboard handling and storage is a subset of the ship supply chain stage, addressed by TRL, and addressing the following:

- Fuel supply system (piping)

- Fuel tanks (materials, capacity, location)

- Venting and detection

- Compliance of crew

![]()

The ship supply chain stage covers all operations onboard. IRL and CRL are assessed at this level.

![]()

Propulsion is a subset of the ship supply chain stage, addressed by TRL, and addresses the following:

- Fuel cell systems

- Internal combustion engines (including dual fuel)

- Reformers

- Electric motors

- Batteries (including hybrid)

Fuel categories

- E-fuels

- Blue fuels

- Biofuels

- Other solutions

E-fuels (electrofuels, also referred to as re-electrofuels): Fuels produced from sustainable natural resources that use hydrogen as a carrier or as the final output.

Blue fuels (natural gas with carbon capture, also referred to as ng-fuels): Fuels produced from natural gas with CCS produce low-carbon hydrogen as a carrier or as the final output

Bio-fuels (sustainable biomass-derived fuels): Fuels aim to be net zero by releasing an amount of carbon dioxide equivalent to that captured in creating the biomass resource material.

In addition to zero carbon fuels, technologies such as nuclear and electrification (batteries) are also assessed in the Zero Carbon Fuel Monitor.

Further development

The Zero Carbon Fuel Monitor will be continuously updated, refined and developed as the outlook changes. We appreciate all comments, contributions and suggestions that help develop the concept and increase its impact in achieving zero carbon shipping by 2050.