LR hosted the world’s first workshop on full scale hydrodynamic computer simulations at their Global Technology Centre in Southampton last month. Ship designers from around the world came together with the aim of building confidence in the accuracy of ship scale Computational Fluid Dynamics (CFD) modelling within the marine sector.

This is the first time that the industry has openly compared full scale CFD with comprehensive measurements. Through comparisons of blind simulation results submitted by participants, and the speed trials carried out by LR, the workshop demonstrated that ship speed could be predicted within approximately 4% of actual trial speeds.

The workshop is a key step on the path to making CFD the final verification of ship scale design performance, rather than relying on scale model tests. The transition to this approach will help reduce design costs and provide a greater opportunity to develop more energy efficient ship designs.

Participants from 15 countries provided details of their CFD modelling and discussed the reasons for any differences to help develop industry guidance for ship scale CFD modelling. This guidance will increase the accuracy of ship scale CFD and help make CFD a primary ship performance and design tool for the marine industry.

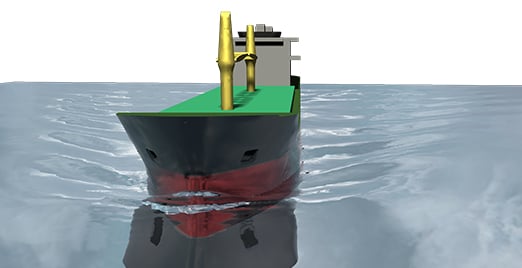

Ship scale CFD simulation of the subject vessel, made with StarCCM+ code

The subject ship of the workshop was a 16.9k DWT general cargo vessel – an ideal candidate for CFD validation as the vessel has a simple geometrical configuration: single screw, no thrusters, no bulbous bow, and no energy saving devices.

The participants blind simulation results were compared as part of the following four modelling scenarios: ship scale resistance simulation (4 speeds), ship scale propeller open water characteristics computations (5 speeds), ship scale self-propulsion simulation (3 speeds) and ship scale propeller cavitation (1 condition).

LR’s Innovation Strategy and Research Director Luis Benito commented: "In the era of 'simulation', CFD technology and advanced computing power plays a key role in predicting performance ahead of reality. LR’s Ship Performance Group, part of our Technical Investigation Department, has engaged world experts by sharing measured performance data from an operating ship and facilitating a discussion of the different CFD modelling approaches used by the participants. This meeting has created a community among industry and helped to further enhance LR's own CFD modelling expertise. LR CFD in turn predicts reality on aspects of ship performance like few others do in the market. This is why I am so proud of LR hosting and chairing the first international full scale numerical modelling workshop."

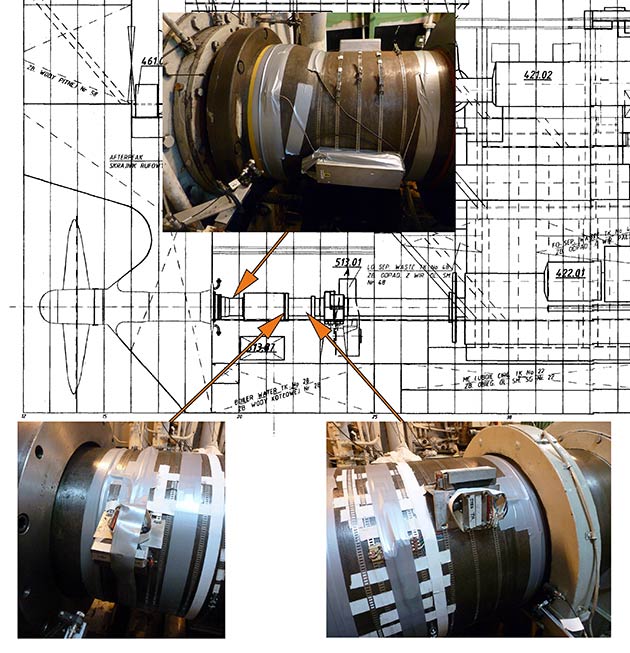

Images of the performance measurement kit installed on the propeller shaft of the subject vessel.