New technology aims to usher in era of fourth industrial revolution in shipbuilding industry.

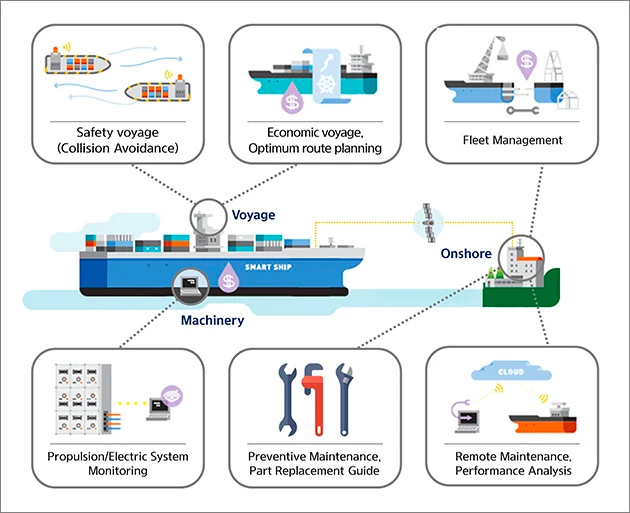

Hyundai Heavy Industries (HHI), the world’s largest shipbuilder, has today announced the development of Integrated Smart Ship Solution (ISSS), its proprietary ICT technology capable of realising economical and reliable navigation and management of ships. ISSS is the first of its kind in the shipbuilding industry.

The solution standardises ways of navigation varying depending on levels of skills and experiences of navigators, collects and analyses real-time information on navigations, and thus will play a role in enhancing efficiency and safety of ships. It is predicted that the solution cut annual operating cost by 6%.

By 2019 the IMO is set to introduce e-Navigation, a strategy to increase safety of navigation in commercial shipping through better organisation of data on ships. Therefore the demand for smart ships is expected to grow in the coming months.

Smart ship technology is a system that helps ships operate more efficiently through the use of ICT and big data. HHI first developed smart ship technology in 2011 and has applied the system to around 300 ships so far. Additionally, in May this year HHI signed a memorandum of understanding to establish a partnership in the smart ship sector with the National Shipping Company of Saudi Arabia (Bahri).

Lloyd’s Register’s Luis Benito, Innovation, Strategy and Research Director, Marine and Offshore commented: “HHI’s technology seeks to align with delivering the key benefits we believe the maritime industry will most benefit from through the adoption of connected, digital and autonomous technologies as the next generation of shipping embraces digitalisation. According to Clarkson Research, about 6,500 ships are to be ordered globally for the next five years. Considering the global shipbuilding market share HHI takes up now, ISSS is to be installed on approximately 700 ships for the comparable time period.”

ISSS provides a wide range of ship information to operators including optimal navigation routes and navigation speed, along with a slope status of the front and back hull of a ship that minimise resistances a ship takes on voyage. The solution allows safer and more efficient management of ships by collecting and analysing energy data and monitoring status of engines and propellers. The ICT solution already completed field tests as well by being mounted on a 6,500 PCTC and a 250,000 DWT VLOC.

An HHI official said: “We will continue to exert our efforts to lead the global shipbuilding market with differentiated technological edges through the digital innovation.”

Glovis Challenge, 6,500 PCTC with Integrated Smart Ship Solution