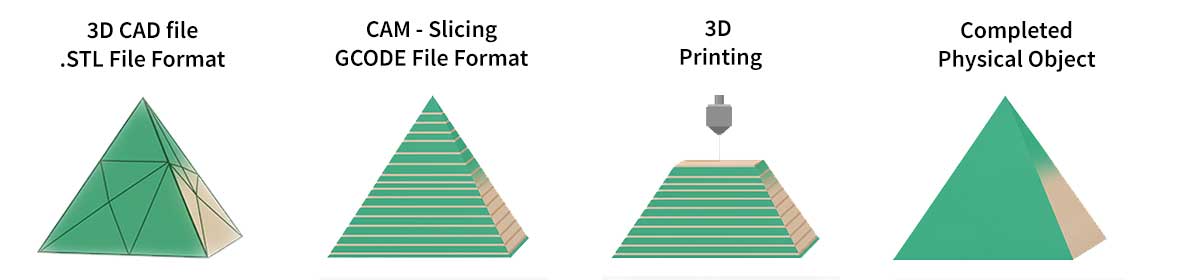

Additive Manufacturing builds components layer by layer directly from a digital model, closer to where they’re needed, reducing lead times and transforming supply chains. Minimise asset downtime and stop waiting weeks for critical parts with sustainable manufacturing.

Additive Manufacturing (AM) can help produce certified parts on demand, shorten production cycles, strengthen supply chain resilience and reduce environmental impacts. AM (also known as 3D printing) is reshaping shipbuilding and fleet operations.

LR offers Additive Manufacturing Certification and Guidance Notes covering the manufacture, testing, and certification of metallic parts, polymer parts, metallic wire and powders. We also provide facility qualification to ensure a consistent framework for classification and certification. With LR, clients can develop AM products that meet quality standards with confidence, assuring both safety and compliance.

Digital Design to Certified Component Performance

Classification and certification prove your AM parts meet the same integrity standards as conventional parts throughout their lifecycle. Reduce risk, satisfy regulators, insurers and standardise quality across fleets and suppliers with an LR-certified route from feedstock to material and part approval.

- Validated Expertise: Classed and certified parts demonstrate proven performance in AM design, materials and safety.

- Industry Recognition: Certification provides credible, audit-ready assurance for customers, insurers and regulators.

- Feedstock Certification: verifies powder & wire quality and traceability to secure consistent builds.

- Facility Qualification: demonstrates that your additive manufacturing controls and quality assurance can reliably deliver high-quality outputs.

- Parts Certification: Showcase that your finished parts comply with industry standards and are class-ready.

Certification Pathways for Additive Manufacturing Processes

Our classification and certification give you the same confidence and acceptance as conventional parts, such as castings and forgings. We employ a risk-matched (criticality-based) approach, ensuring that each part follows the fastest, yet safe, approval path.

Certification pathways

- Design Review: Your digital design is assessed for integrity and intended service.

- Material Suitability: We confirm the suitability of the material and its properties for the intended purpose.

- Manufacturing Controls: Your AM process controls are quality assured and verified for repeatable quality.

Technologies & materials covered

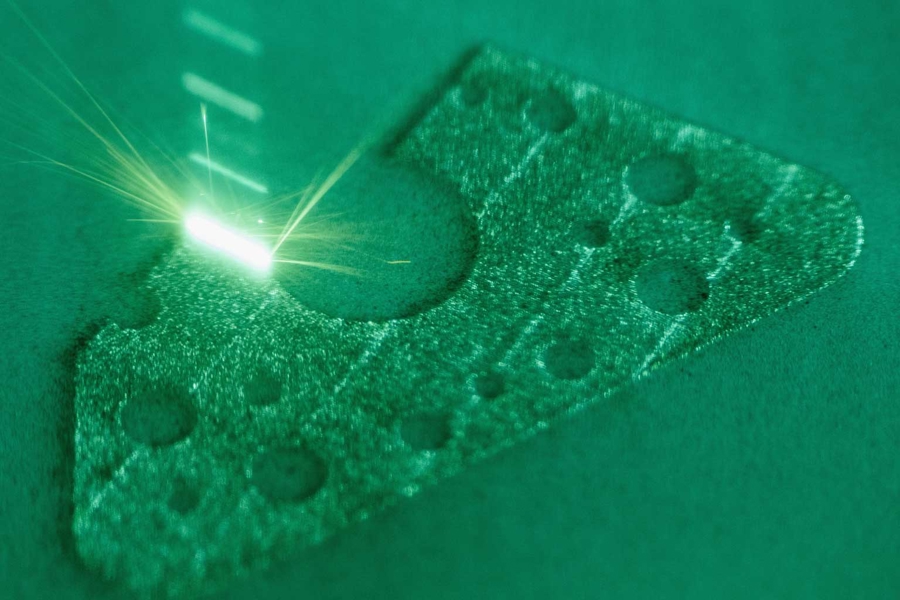

- Established AM: Powder Bed Fusion (PBF), Directed Energy Deposition (DED), and Binder Jetting (BJT).

- Maritime Materials: steels, non-ferrous alloys (e.g., copper, aluminium) and engineering polymers.

When standards don’t yet exist

- New Processes or Materials: Co-develop a certification pathway with you.

- Non-standard Designs: Certified via risk-based or goal-based routes, aligned with LR class requirements.

Trusted Additive Manufacturing Certification from Feedstock to class-ready parts

Lloyd's Register's independent assurance provides the same confidence in your AM part as in those produced using conventional techniques, with certification to class requirements that encompass feedstock, facility, printed material, and class-ready parts.

Our AM Assurance Pathway goes beyond box-ticking compliance by mapping the fastest safe route to approval, so you reduce risk, accelerate qualification, and build trust in a technology that’s reshaping maritime supply chains.

Backed by deep technical expertise and LR’s AM Guidance Notes, we deliver transparency and efficiency across the product lifecycle, helping your teams understand requirements, optimise qualification plans, and prove performance in service. Grounded in safety and sustainability, we enable innovation while protecting reliability in critical maritime applications.

Frequently Asked Questions

A part is suitable for additive manufacturing when it provides clear benefits over traditional methods, such as enabling complex designs, customisation, or combining multiple components into one. Key factors include potential for topology optimisation, shorter lead times, lower shipping and tooling costs, and improved material efficiency. The decision should also consider material properties, part size, production volume, and effects on downstream processes such as coating, joining, inspection, and maintenance. Manufacturers must also ensure the AM process meets all regulatory, application, and service-life requirements.

Classification applies to AM parts that are essential to a classed vessel or marine equipment and requires full compliance with LR Rules and Regulations, including design appraisal, use of LR-certified feedstock, facility qualification, and LR surveys during manufacturing and testing. Certification is for parts used in marine or offshore applications that do not require classification but must meet industry standards, project specifications, or OEM requirements. Certification includes design appraisal, facility and feedstock verification, and inspection or testing, but does not require full compliance with LR Rules for classed assets.

LR certification independently verifies that AM parts, processes, and materials meet recognised standards, reducing technical and commercial risk. It demonstrates compliance with regulatory or project requirements, builds confidence in quality and performance, and supports client and stakeholder acceptance. Certification also helps manufacturers stand out in the market, streamline procurement with LR-approved feedstocks and facilities, and minimise costly rework or delays by validating designs and processes early.

The certification process starts with a design review to confirm compliance with standards and suitability for the intended use. LR then verifies the AM facility, including equipment, quality systems, and personnel, and checks feedstock conformity. Part qualification involves approval builds and testing under LR survey to ensure material and mechanical properties meet specifications. LR issues a certificate after successful inspection and testing, supported by complete documentation. Facility and feedstock certifications are valid for three years and require periodic audits and requalification.

LR provides comprehensive support throughout certification and qualification, including early design review, advisory services, feedstock certification or witnessed testing, and facility qualification through audits and documentation checks. They assist with process and part qualification by witnessing approval builds and testing, offer guidance on operator training and competency, and apply technology qualification for new processes. LR also delivers ongoing support through periodic audits, requalification, and continuous improvement reviews to ensure compliance, reduce risk, and build confidence in AM parts and processes.