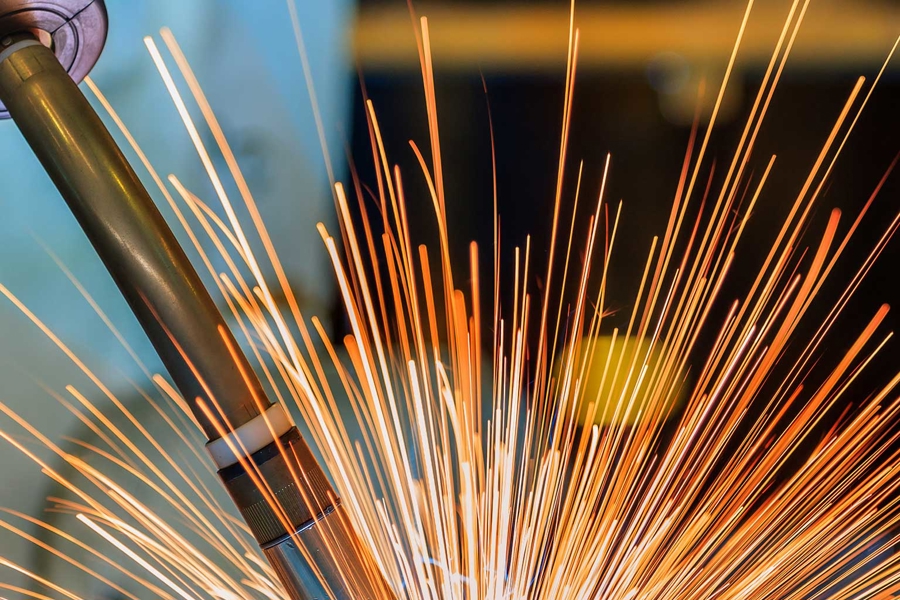

Having a third party endorse your highly qualified welders and welding operators provides confidence that your business complies with the required marine standards, and LR rules and regulations.

LR provides all important tests for national and global requirements for the maritime environment, that will assure your customers that your team meets their expectations. You will be able to prove that your team is up for any challenge that calls for high-quality welds.

From welding consumables approval, including welding wires and rods, and covered electrodes and flux-cored wires, to qualifying the welders and welding operators, LR’s team of experts will ensure the materials and procedures used meet the high standards and regulations demanded in the maritime industry.

Welding overview

Welding consumables

With an LR approval certificate, demonstrate to your clients that the quality of welding consumables meets LR requirements. By choosing annual testing, you are assured that your consumables always meet the latest requirements.

Weld failure analysis

Find out the real reason a weld may fail. LR has a laboratory engaged in failure analysis work that will provide you with accurate information.

Works approval for maritime for fusion welded pressure vessels

Ageing vessels mean a high demand for workshops in yards, manufacturing sites, repairs and scrapping. LR approval proves that you are up to the required quality and safety standards when handling components or important parts of the vessels.

This service can be provided on a project or facility basis, so that your customers can find you in our database.

In the maritime industry, it’s not enough to have the best welder and welding operators, you also need to have a reliable testing process. LR provides a Non-Destructive Examination (NDE) Gap analysis for compliance with LR rules.

Our services

Welding qualifications based on the following standards in relation to LR Rule requirements:

- ISO 9606, AWS D1.1, ISO 17660 (manual welding)

- ISO 14732 (operators)

- AWS D3.6M, ISO 15618-1 (underwater welding)

- ASME sec. IX (welding of pressure vessels/equipment)

- ISO 13585 (brazers)

- EN 14555 (stud welding)

Welding procedures approval according to:

- EN ISO 15614 (-1 to -13)

- EN ISO 14555 (stud welding)

- EN 13134 (brazing)

- LR rules for welding

Why LR?

LR's third-party certification services provide confidence to manufacturers and clients by ensuring products and components meet high standards, offering compliance and performance services to make businesses safe, sustainable, and efficient. These go beyond pass/fail assessments by connecting clients with expertise and sharing domain experience to add value and clarify technical details.

Founded on social purpose values, LR focuses on safety and delivering sustainable change for the future. LR provide technical capabilities through digital services, utilising data and real-time intelligence for transparency and oversight throughout project lifecycles.

Resources

-

LR Approvals

-

Introduction: Approved welding consumables

-

Supplementary List of Certified Welding Consumables

-

Guidelines for Qualification of Welding Procedures, Welders and Weldability

-

Procedures for Approval of Repair Procedures

-

Procedures for Approval of Welding Consumables and Manufacture of Fabricated Steel Sections